5 Important Cheese Making Sanitization Tips

11th May 2021

As with any food, it’s essential to use clean, sanitized materials when making homemade cheese. Don’t worry; you don’t have to use any harsh chemicals! Sanitizing your cheesemaking equipment is easy and will help you make healthy cheese that’s free of pathogens.

Sanitize any equipment that may come in contact with your cheese and ingredients throughout the cheesemaking process. White vinegar and boiling water are both food-safe disinfectants that can create a safe, sanitary environment for cheesemaking.

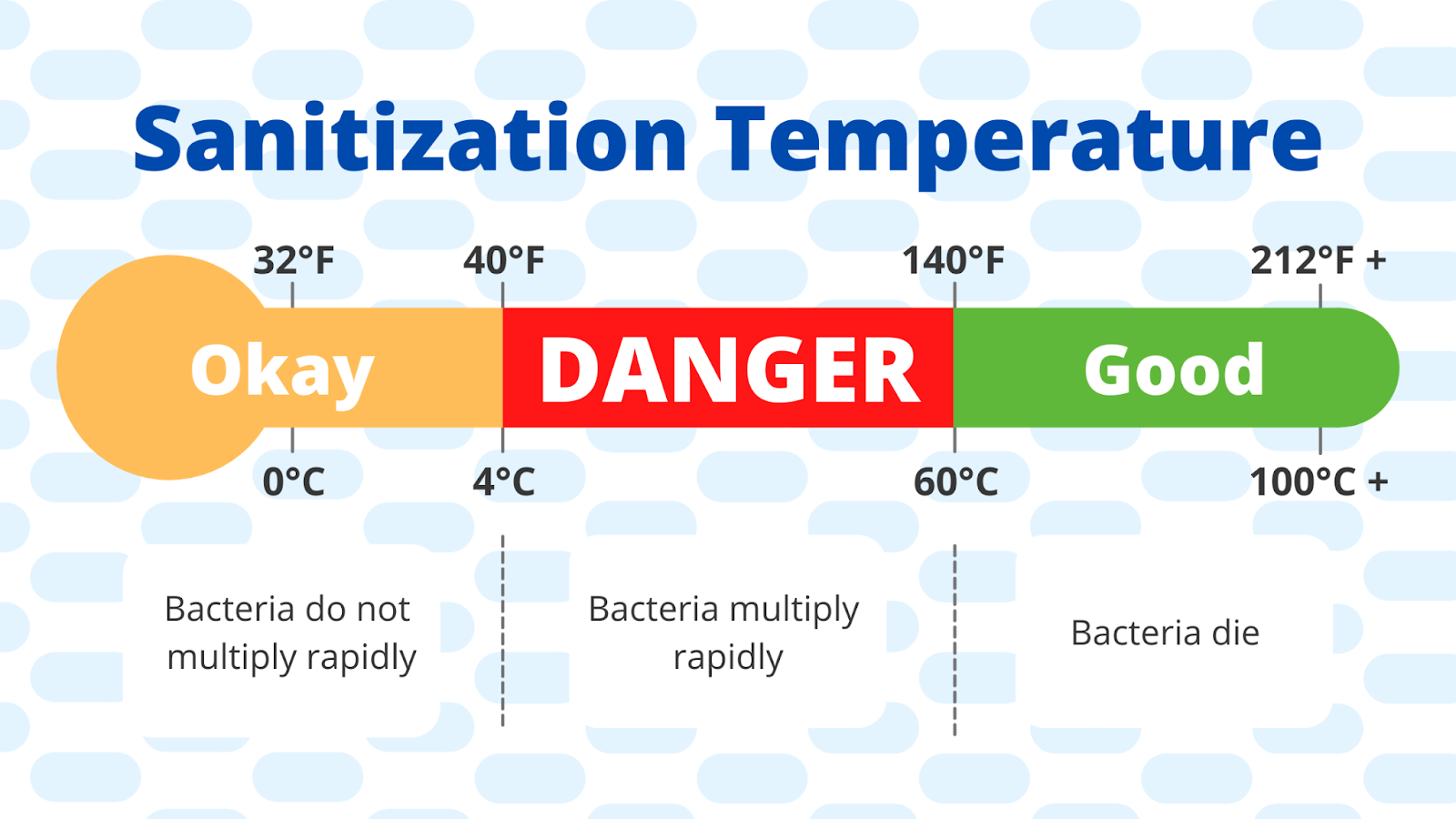

So long as you heat your equipment above 140°F (60°C), you can feel safe that you’re starting with a clean work environment. Still, that doesn’t cover everything. You may be interested to see why it’s important to sanitize each piece of your cheesemaking equipment and, sometimes, even the ingredients.

Follow these 5 tips for safer homemade cheese:

- Use caution when using raw milk.

- Don’t forget to sanitize your cooking equipment.

- Sanitize your cheese moulds.

- Be sure to think about where you will be storing or aging your cheese.

- Consider other specialized and food-safe sanitizers.

Raw milk can be an excellent ingredient for truly delicious homemade cheese, but it can also carry various potentially harmful pathogens. The bulk of store-bought milk is pasteurized to help establish food safety. Embracing pasteurized milk has helped to make milk safe for human consumption and has even been credited with preventing epidemiological outbreaks.

While you may yield a cheese with better flavor by using raw milk, you should make sure it is coming from a trustworthy source. When milk is not pasteurized, things like sanitary milking conditions and equipment become even more relevant to milk quality. If you are unable to find a source you can trust near you, you might want to stick to pasteurized milk to err on the side of caution.

Now, you may argue that milk is heated anyway when making cheese, so what does it matter if it’s pasteurized or not? While most cheese recipes call for milk to be heated, it’s most often not heated to the same degree that it would be during pasteurization. As a result, raw milk can potentially carry pathogens past the heating step of cheesemaking. Even if all of the bacteria are killed, their prolonged presence in the milk may add toxins that are unaffected by heat.

As the most central ingredient to cheese, any pathogens present in the milk will inevitably be present in the cheese produced with it, so pasteurization is your friend. Conversely, ultra-pasteurized milk is typically not recommended for cheesemaking. The extreme heat used in the ultra-pasteurization process changes the inherent properties of the milk and can adversely affect the texture and flavor of cheeses made with it.

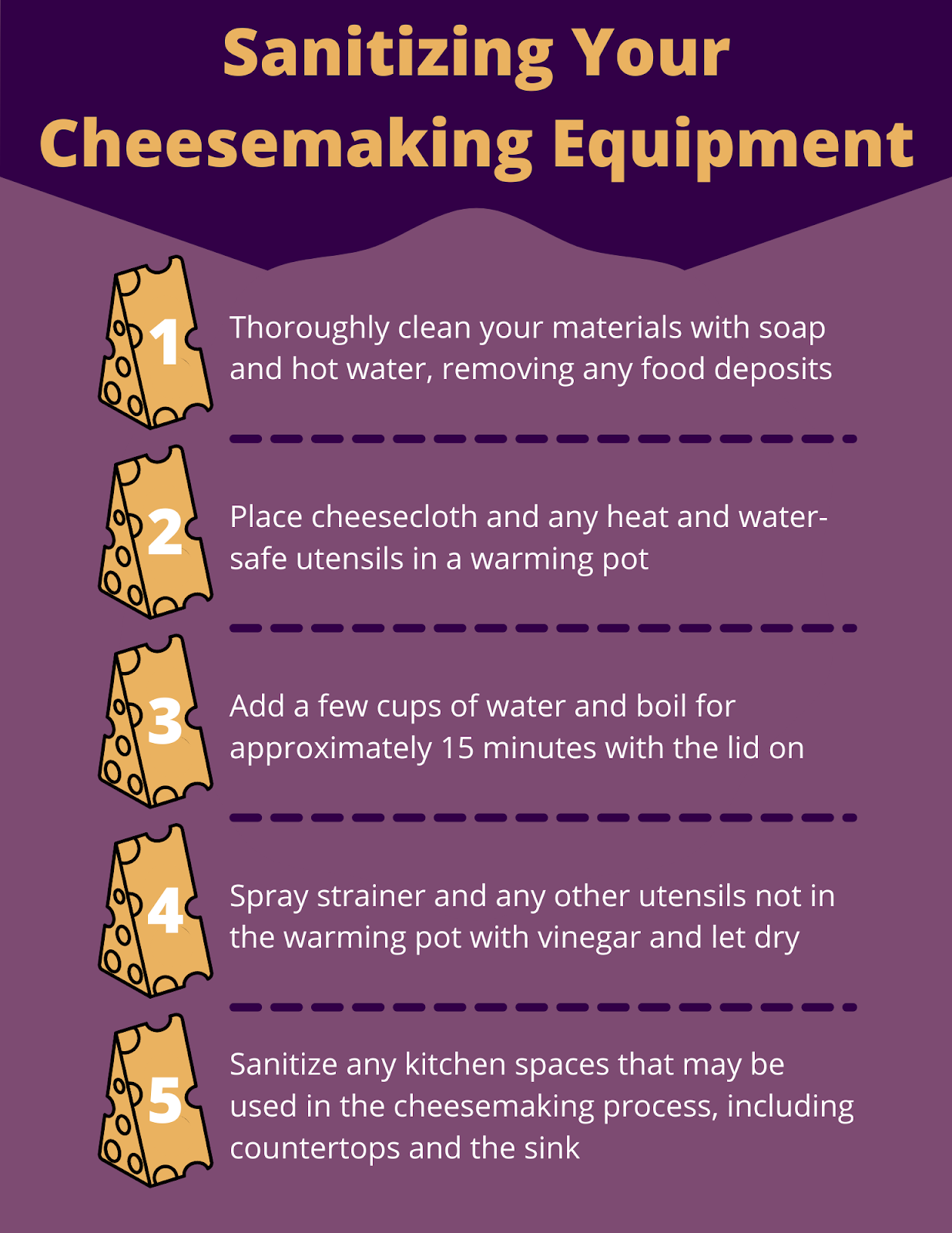

Being that your warming pot, cheesecloth, and strainer will all come in direct contact with your cheesemaking ingredients, it’s crucial to ensure they aren’t adding any unwanted bacteria hitchhikers to your recipe. There’s plenty of equipment you may use that you won’t want to stop to sanitize while you’re making your cheese, so be sure to include your cheesecloth, measuring spoons, skimmer, spatula and strainer.

Keep your newly sanitized equipment in an area you sanitized as well. If you are straining over the sink, make sure to use vinegar or another disinfectant solution to clean the sink before you start straining. Even your countertops can impart bacteria on your utensils and cookware, so be wary of where you set down your pot lid or spoon.

The sanitization of this equipment is imperative to the overall quality of the cheese you’ll produce. Improper sanitization of these materials can introduce bacteria and pathogens throughout your cheese, not just on the outside. This can lead to premature spoilage and can even get you sick. Not all stinky cheese is good cheese, so be sure to sanitize your equipment to keep your cheese smelling and tasting as it should.

A cheese mould—the forming tool, not the fungus—is one of the last things an aged cheese will touch before you set it to ripen, so it’s vital to ensure no unwanted bacteria or spores are being transferred to your cheese by the moulds. Certain microbes are necessary for some cheeses to get their characteristic features and tastes, but you must control those microbes for safe and consistent results.

For example, blue cheese requires Penicillium Roqueforti to develop that ripe smell and savory flavor. If other bacterial cultures were present, they would compete with the Penicillium Roqueforti and affect the cheese in a way other than expected. The presence of unwanted bacteria or spores can impair a cheese’s ability to age and cause premature spoilage. So, in case you hadn’t gathered by now, sanitize! A benefit of metal moulds is that you can sanitize them with your warming pot in boiling water.

Improper sanitization of cheese moulds can inhibit your cheese’s ability to develop a proper rind and render a typically edible rind inedible. If the invasive bacteria is strong enough, it can even ruin the interior of the cheese. Save yourself the heartbreak of a ripened cheese gone too ripe and sanitize those moulds!

Sanitary conditions don’t end when you have finished making your cheese or once you store it. Ensure you sanitize the containers you will be keeping your cheese in to help prevent the introduction of potentially harmful microbes. It might not come to mind, but even the “clean” containers in your cabinet can come into contact with airborne microbes that can adversely affect the nature of your stored cheese.

Storing cheese in an environment that has been sanitized serves to prolong its shelf life, especially for those homemade cheeses that don’t include artificial preservatives. Ingredients like salt and citric acid may help curb bacteria’s growth, but starting with a bacteria-free environment is best.

While boiling water and vinegar are effective sanitizers, you might like to be extra sure that your equipment is safe to make your cheese. If you’re looking to make an aged cheese, a sanitized environment is vital to ensuring only added molds and cultures affect your cheese. Even cheeses that require little to no aging should be made with sanitized equipment to help ensure they are safe to eat and will last when stored. Our selection of sanitizers makes for easy equipment sanitization and can even help to dissolve stubborn milkstone deposits. For your equipment that can’t be heated to temperatures that would kill bacteria, Star San Acid Sanitizer is a great alternative. It only requires 30 seconds of contact time to be effective, too.

Bonus! Some things you might not think about:

When dealing with things as invisible to the naked eye as bacteria, it can be challenging to think of everything that might introduce malicious microbes to your recipes. When you’re sanitizing your equipment, don’t forget the smaller items like your thermometer or curd knife.

There’s also another way to sanitize your equipment that saves you the effort of boiling and spares you the smell of vinegar: your dishwasher. If your dishwasher is certified to NSF/ANSI Standard 184, you can sanitize your equipment in the dishwasher using its “sanitize” function.4 Just be sure to handle the equipment with clean hands when removing it for use!

Sanitization is a vital step to the cheesemaking process for the safety of both you and your cheese. It may seem strange that a culinary process so dependent on bacteria would require such diligence in eliminating bacteria, but starting with a blank slate allows you to be sure what is in your cheese, even if you can’t see it. Milk and cheese are very chemically diverse substances, so providing them controlled environments makes for a more predictable reaction. Still, the hobby of cheesemaking is full of surprises, and that’s half the fun. Just be sure to sanitize your equipment so a pathogen isn’t one of those surprises!

*Be sure that the heat won’t damage anything you put in the pot with boiling water. If there is the potential for the item to be damaged, use the vinegar method or one of our other sanitizers instead.

Sources:

- https://mbio.asm.org/content/5/2/e00013-14.full

- https://opentextbc.ca/foodsafety/chapter/preventing-foodborne-illness/

- https://www.researchgate.net/profile/Surajit-Sarkar-6/publication/283023438_Microbiological_Considerations_Pasteurized_Milk/links/568b440b08aebccc4e1a3ede/Microbiological-Considerations-Pasteurized-Milk.pdf

- https://www.nsf.org/knowledge-library/dishwashers